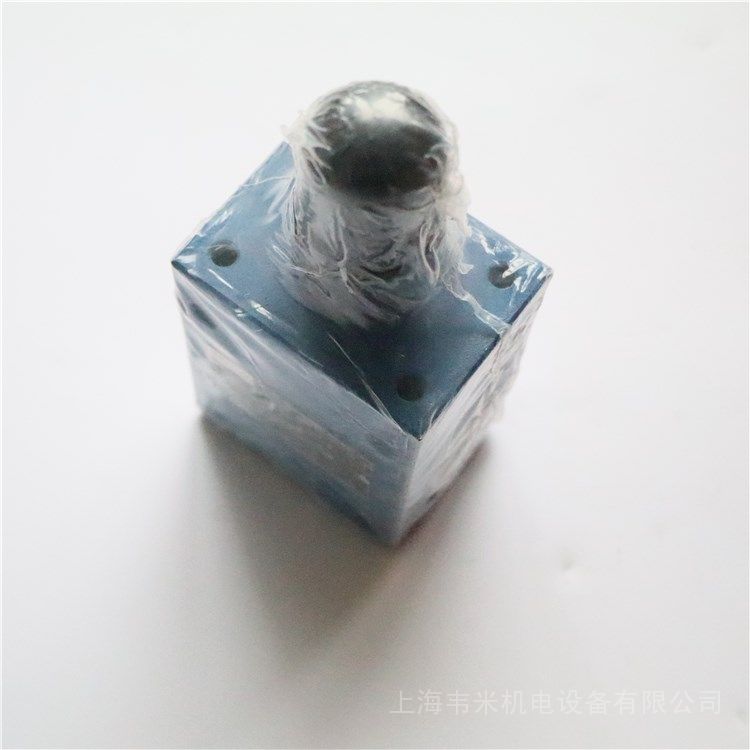

REXROTH溢流閥DBDS10G1A/100 R900424738,德國(guó)力士樂溢流閥訂貨號(hào)和型號(hào),現(xiàn)貨庫(kù)存產(chǎn)品,價(jià)格優(yōu)惠,上海韋米機(jī)電設(shè)備有限公司主營(yíng)銷售產(chǎn)品,原廠原裝,熱誠(chéng)歡迎新老客戶咨詢購(gòu)買!

壓力控制閥

壓力控制閥的作用:

1、用來控制液壓系統(tǒng)中油液壓力;

1)溢流閥:直動(dòng)式溢流閥、先導(dǎo)式溢流閥

2)減壓閥

2、以壓力為控制信號(hào)實(shí)現(xiàn)油路通斷。

3)順序閥

4)壓力繼電器

共同工作原理:利用作用于閥心上的液壓力與彈簧力相平衡的原理進(jìn)行工作。

溢流閥應(yīng)用實(shí)例

(1)為定量泵系統(tǒng)溢流穩(wěn)壓和定量泵、節(jié)流閥并聯(lián),閥口常開。

(2)變量泵系統(tǒng)提供過載保護(hù)

和變量泵組合,正常工作時(shí)閥口關(guān)閉,過載時(shí)打開,起安全保護(hù)作用,故又稱安全閥。

(3)實(shí)現(xiàn)遠(yuǎn)程調(diào)壓 p遠(yuǎn)程< p主調(diào)

(4)系統(tǒng)卸荷和多級(jí)調(diào)壓 和二位二通閥組合(先導(dǎo)式)

(5)形成背壓

減壓閥用于降低并穩(wěn)定系統(tǒng)中某一支路的油液壓力,常用于夾緊、控制等油路中。

順序閥是一種利用壓力控制閥口通斷的壓力閥,因用于控制多個(gè)執(zhí)行元件的動(dòng)作順序而得名。按控制油來源不同分內(nèi)控和外控,按彈簧腔泄漏油引出方式不同分內(nèi)泄和外泄。

壓力繼電器功用:根據(jù)系統(tǒng)壓力變化,自動(dòng)接通或斷開電路,實(shí)現(xiàn)程序控制或安全保護(hù)。

工作原理: pk> pT時(shí),柱塞上升,發(fā)出信號(hào)pk< pT時(shí),柱塞下降,斷開信號(hào)。

流體控制是利用流體的各種控制元件(各種泵、閥門、油缸)及液壓系統(tǒng)附件(過濾器、管路接頭、液位計(jì)、壓力儀表等),組成控制閉式回路,以進(jìn)行自動(dòng)控制。按其工作介質(zhì)可分為以下兩種:

(1)液壓控制 液壓控制用油液作為工作介質(zhì),故能把由于功率的損耗而產(chǎn)生的熱量,從發(fā)生的地方帶到別處,這樣在一定的功率情況下,可以大大減小部件的尺寸;從負(fù)載的影響看,液壓系統(tǒng)具有機(jī)械上的剛性,用在閉環(huán)系統(tǒng)中,定位剛度較大,位置誤差較小;與機(jī)械機(jī)構(gòu)相比,液壓執(zhí)行器的響應(yīng)速度較高,能高速啟動(dòng)、制動(dòng)與反向,同時(shí)其力矩—慣量比也較大,因而其加速能力較強(qiáng);液壓傳動(dòng)易實(shí)現(xiàn)無級(jí)調(diào)速,具有自身潤(rùn)滑等優(yōu)點(diǎn)。

液壓系統(tǒng)的缺點(diǎn)是:由于難以避免漏油,因而會(huì)影響運(yùn)動(dòng)的平穩(wěn)性,并使效率降低;油液被塵埃或流體截止中其他雜質(zhì)污損后,會(huì)造成液控系統(tǒng)發(fā)生故障;油液具有易燃性,有引起爆炸的危險(xiǎn);液體粘度受溫度影響,使供油量和執(zhí)行機(jī)構(gòu)的運(yùn)動(dòng)速度不穩(wěn)定;油液中有空氣會(huì)引起工作機(jī)構(gòu)的不均勻跳動(dòng);就處理小功率信號(hào)的數(shù)學(xué)運(yùn)算、誤差檢測(cè)、放大、測(cè)試與補(bǔ)償?shù)裙δ芏裕簤貉b置不如電子或機(jī)電裝置那樣靈活、線性、準(zhǔn)確和方便,因而在控制系統(tǒng)的小功率部分,一般不宜采用,主要應(yīng)用于系統(tǒng)的動(dòng)力部分。

REXROTH溢流閥DBDS10G1A/100 R900424738

德國(guó)力士樂REXROTH溢流閥訂貨號(hào)和型號(hào):

R900424738 DBDS10G1A/100

R900364483 DBDS10G1A/100SO130

R900409673 DBDS10G1A/100SO450

R900342450 DBDS10G1A/100SO74

R900439606 DBDS10G1A/100W1

R900567555 DBDS10G1A/100W100

R900347490 DBDS10G1A/100W40

R900916880 DBDS10G1A/100-075/12

R901020245 DBDS10G1A/100-25/59

R901020237 DBDS10G1A/100-30/59

R901005956 DBDS10G1A/100-35

R901156100 DBDS10G1A/100-40

R901370855 DBDS10G1A/100-50

R901060953 DBDS10G1A/100-55

R901189278 DBDS10G1A/100-60

R900953867 DBDS10G1A/100-70

R900341363 DBDS10G1A/100/12

R900436001 DBDS10G1A/100/2

R900470504 DBDS10G1A/100/5

R901256798 DBDS10G1A/100/59

R900572352 DBDS10G1A/100B

R900420277 DBDS10G1A/100B

R900423746 DBDS10G1A/100B

R900769619 DBDS10G1A/100E

R900487479 DBDS10G1A/100J

R901052283 DBDS10G1A/100J=TE

R901307340 DBDS10G1A/100P025

R901307339 DBDS10G1A/100P065

R900935424 DBDS10G1A/100P080

R900424739 DBDS10G1A/100V

R900389968 DBDS10G1A/100VW40

R900349041 DBDS10G1A/100V/12

R900474917 DBDS10G1A/100V/5

R900924255 DBDS10G1A/100VB

R901181521 DBDS10G1A/100VE

R901233054 DBDS10G1A/105E

R900466366 DBDS10G1A/110/5B

R900423744 DBDS10G1A/110B

R901034804 DBDS10G1A/110E

R900386642 DBDS10G1A/110JB

R900468767 DBDS10G1A/110VB

R900572452 DBDS10G1A/120B

R900772782 DBDS10G1A/120E

R900572453 DBDS10G1A/125B

R901185590 DBDS10G1A/125E

R900572454 DBDS10G1A/130B

R900778044 DBDS10G1A/130E

R900921193 DBDS10G1A/130VB

R900572455 DBDS10G1A/135B

R901185479 DBDS10G1A/135E

R900572456 DBDS10G1A/140B

R901026426 DBDS10G1A/140E

R900572457 DBDS10G1A/150B

R900769507 DBDS10G1A/150E

R900572458 DBDS10G1A/155B

R900572459 DBDS10G1A/160B

R901136834 DBDS10G1A/160E

R901117802 DBDS10G1A/165E

R900429968 DBDS10G1A/170

R900429968 DBDS10G1A/170

R900370316 DBDS10G1A/170/5B

R900424808 DBDS10G1A/170B

R900773192 DBDS10G1A/170E

R900429947 DBDS10G1A/170VB

R900909997 DBDS10G1A/175B

R900572546 DBDS10G1A/180B

R900769606 DBDS10G1A/180E

R901235516 DBDS10G1A/180VE

R900572547 DBDS10G1A/190B

R901013662 DBDS10G1A/190E

R900424140 DBDS10G1A/200

R900433779 DBDS10G1A/200

R900340877 DBDS10G1A/200SO130

R900344863 DBDS10G1A/200SO15

R900493041 DBDS10G1A/200SO27

R900497024 DBDS10G1A/200SO31

R900360512 DBDS10G1A/200SO74

R900400659 DBDS10G1A/200W1

R900703583 DBDS10G1A/200-100

R900731004 DBDS10G1A/200-110

R901210090 DBDS10G1A/200-120

R901037453 DBDS10G1A/200-130

R900953705 DBDS10G1A/200-140

R900940672 DBDS10G1A/200-150

R900910458 DBDS10G1A/200-160

R901117172 DBDS10G1A/200-165

R900962532 DBDS10G1A/200-170

R900971263 DBDS10G1A/200-180

R901256664 DBDS10G1A/200-185

R900341591 DBDS10G1A/200/12

R900392231 DBDS10G1A/200/12SO60

R900442081 DBDS10G1A/200/2

R900470505 DBDS10G1A/200/5

R900946730 DBDS10G1A/200/50

R900572548 DBDS10G1A/200B

R900769540 DBDS10G1A/200E

R900458636 DBDS10G1A/200J

R900563775 DBDS10G1A/200J/12

R901052252 DBDS10G1A/200J=TE

R900520756 DBDS10G1A/200JV

R901240746 DBDS10G1A/200P100

R900951431 DBDS10G1A/200P140

R901347971 DBDS10G1A/200P140/12

R901355397 DBDS10G1A/200P160SO60

R900977656 DBDS10G1A/200P180

R900424741 DBDS10G1A/200V

R900391769 DBDS10G1A/200VSO60

R900343963 DBDS10G1A/200V/12

R900475531 DBDS10G1A/200V/5

R900940422 DBDS10G1A/200VB

R901014788 DBDS10G1A/200VE

R900572549 DBDS10G1A/205B

R900774958 DBDS10G1A/205E

R901229978 DBDS10G1A/210/12E

R900426099 DBDS10G1A/210B

R900769379 DBDS10G1A/210E

R900400298 DBDS10G1A/210VB

R901238752 DBDS10G1A/210VE

R901357023 DBDS10G1A/215E

R900572618 DBDS10G1A/220B

R900772319 DBDS10G1A/220E

R900941189 DBDS10G1A/220VB

R901378805 DBDS10G1A/220VE

R900572619 DBDS10G1A/230B

R900769565 DBDS10G1A/230E

R901395602 DBDS10G1A/230VE

R900572620 DBDS10G1A/240B

R900783238 DBDS10G1A/240E

R900423743 DBDS10G1A/25

R900338391 DBDS10G1A/25SO450

R900391770 DBDS10G1A/25SO60

R900401161 DBDS10G1A/25SO74

R900439333 DBDS10G1A/25W1

R900397355 DBDS10G1A/25W100

R900929857 DBDS10G1A/25-10

R900930354 DBDS10G1A/25-10V

R900913880 DBDS10G1A/25-20

R900923249 DBDS10G1A/25-20V

R900351411 DBDS10G1A/25/12

R900471709 DBDS10G1A/25/5

R900408790 DBDS10G1A/25/V/5

R900572621 DBDS10G1A/250B

R901012705 DBDS10G1A/250E

R901445518 DBDS10G1A/250VE

R900499604 DBDS10G1A/25J

R901053363 DBDS10G1A/25J=TE

R900903942 DBDS10G1A/25P15

R900423889 DBDS10G1A/25V

R900346901 DBDS10G1A/25VW1

R900340153 DBDS10G1A/25V/12

R900572622 DBDS10G1A/260B

R901309515 DBDS10G1A/260E

R900965654 DBDS10G1A/275B

R901011611 DBDS10G1A/275E

R900572623 DBDS10G1A/280B

R900773229 DBDS10G1A/280E

R900572624 DBDS10G1A/300B

R901124323 DBDS10G1A/300E

R901402828 DBDS10G1A/305E

R900572289 DBDS10G1A/30B

R900777079 DBDS10G1A/30E

R900968633 DBDS10G1A/30VB

R900769607 DBDS10G1A/30VE

R901083276 DBDS10G1A/310E

R900424742 DBDS10G1A/315

R900332635 DBDS10G1A/315SO130

R900345136 DBDS10G1A/315SO150

R900587880 DBDS10G1A/315SO284

R900419721 DBDS10G1A/315SO60

R900587502 DBDS10G1A/315SO700

R900372286 DBDS10G1A/315SO74

R900560483 DBDS10G1A/315SO770

R900472760 DBDS10G1A/315W1

R901213049 DBDS10G1A/315-120

R901117166 DBDS10G1A/315-190

R901081750 DBDS10G1A/315-200

R900919942 DBDS10G1A/315-220

R900939820 DBDS10G1A/315-220V

R901036708 DBDS10G1A/315-235

R900915091 DBDS10G1A/315-250

R901216827 DBDS10G1A/315-250V

R900771754 DBDS10G1A/315-270

R900724592 DBDS10G1A/315-275

R900911873 DBDS10G1A/315-290V

R900377746 DBDS10G1A/315/12

R900470506 DBDS10G1A/315/5

R901095276 DBDS10G1A/315/59

R900406279 DBDS10G1A/315/V/5

R900424824 DBDS10G1A/315B

R900427241 DBDS10G1A/315B

R900769430 DBDS10G1A/315E

R900474980 DBDS10G1A/315J

R900529736 DBDS10G1A/315J/12

R901052284 DBDS10G1A/315J=TE

R900594748 DBDS10G1A/315MKB

R900977655 DBDS10G1A/315P210

R900940050 DBDS10G1A/315P220

R901330999 DBDS10G1A/315P230

R901352219 DBDS10G1A/315P240

R901302328 DBDS10G1A/315P255

R901194874 DBDS10G1A/315P260

R901142133 DBDS10G1A/315P280

R901439772 DBDS10G1A/315P290

R900938747 DBDS10G1A/315P300

R900424743 DBDS10G1A/315V

R900340488 DBDS10G1A/315V/12

R901124724 DBDS10G1A/315V/12E

R900489852 DBDS10G1A/315VB

R901341414 DBDS10G1A/315VE

R900572904 DBDS10G1A/320B

R901143312 DBDS10G1A/320E

R900572905 DBDS10G1A/330B

R900769509 DBDS10G1A/330E

R900708266 DBDS10G1A/330VB

R900769616 DBDS10G1A/330VE

R900572906 DBDS10G1A/340B

R901004628 DBDS10G1A/340E

R901142782 DBDS10G1A/345E

R900572907 DBDS10G1A/350B

R901010969 DBDS10G1A/350E

R901403960 DBDS10G1A/350VE

R900572290 DBDS10G1A/35B

R901004635 DBDS10G1A/360E

R900776416 DBDS10G1A/370E

R900572908 DBDS10G1A/375B

R901419086 DBDS10G1A/375E

R900424744 DBDS10G1A/400

R900340395 DBDS10G1A/400SO32

R900337132 DBDS10G1A/400W1

R901421159 DBDS10G1A/400-320

R900967544 DBDS10G1A/400-330

R901283265 DBDS10G1A/400-350

R900934571 DBDS10G1A/400-350V

R900558953 DBDS10G1A/400-370

R901243540 DBDS10G1A/400-400

R900342738 DBDS10G1A/400/12

R900482135 DBDS10G1A/400/12SO150

R900535540 DBDS10G1A/400/2

R900471909 DBDS10G1A/400/5

R900343484 DBDS10G1A/400/V/5

R900424799 DBDS10G1A/400B

R900426187 DBDS10G1A/400B

R900787687 DBDS10G1A/400E

R900381337 DBDS10G1A/400J

R900374117 DBDS10G1A/400JSO73

R901052290 DBDS10G1A/400J=TE

R901147801 DBDS10G1A/400P140

R901348424 DBDS10G1A/400P350V

R901055558 DBDS10G1A/400P370

R901356605 DBDS10G1A/400P400

R900437349 DBDS10G1A/400V

R900395060 DBDS10G1A/400V/12

R900466113 DBDS10G1A/400VB

R901260710 DBDS10G1A/400VE

R900904087 DBDS10G1A/40B

R901015106 DBDS10G1A/40E

R901114853 DBDS10G1A/40VE

R900572966 DBDS10G1A/420B

R900773646 DBDS10G1A/420E

R900915769 DBDS10G1A/420VB

R900979785 DBDS10G1A/440B

R901018676 DBDS10G1A/440E

R900572967 DBDS10G1A/450B

R900574646 DBDS10G1A/485B

R900424745 DBDS10G1A/50

R900343409 DBDS10G1A/50SO130

R900497023 DBDS10G1A/50SO31

R900337135 DBDS10G1A/50SO32

R900401662 DBDS10G1A/50SO50

R900366553 DBDS10G1A/50SO74

R900443130 DBDS10G1A/50W1

R900389365 DBDS10G1A/50W40

R900971932 DBDS10G1A/50-15

R901004502 DBDS10G1A/50-35

R900347687 DBDS10G1A/50/12

R900443393 DBDS10G1A/50/2

R900465670 DBDS10G1A/50/5

R900402960 DBDS10G1A/50/V/5

R900572968 DBDS10G1A/500B

R900520689 DBDS10G1A/500BSO999

R900769561 DBDS10G1A/500E

R900572291 DBDS10G1A/50B

R900423742 DBDS10G1A/50B

R900346412 DBDS10G1A/50B

R901055217 DBDS10G1A/50E

R900485835 DBDS10G1A/50J

R901052297 DBDS10G1A/50J=TE

R900560484 DBDS10G1A/50MT

R900424146 DBDS10G1A/50V

R900358827 DBDS10G1A/50V/12

R901131882 DBDS10G1A/50VE

R900618054 DBDS10G1A/520B

R900779659 DBDS10G1A/520E

R900578531 DBDS10G1A/550B

R901000910 DBDS10G1A/550E

R900572292 DBDS10G1A/55B

R901233052 DBDS10G1A/55E

R900572969 DBDS10G1A/600B

R901167592 DBDS10G1A/600E

R900428380 DBDS10G1A/60B

R901040333 DBDS10G1A/60E

R900442462 DBDS10G1A/60VB

R901182277 DBDS10G1A/60VE

R900423814 DBDS10G1A/630

R900344798 DBDS10G1A/630SO150

R900470981 DBDS10G1A/630SO48

R900461768 DBDS10G1A/630SO52

R900781731 DBDS10G1A/630-620

R900350129 DBDS10G1A/630/12

R900431908 DBDS10G1A/630/5

R900477107 DBDS10G1A/630/V/5

R900432798 DBDS10G1A/630B

R901017729 DBDS10G1A/630E

R900486548 DBDS10G1A/630J

R900594747 DBDS10G1A/630MKB

R900748871 DBDS10G1A/630P580V

R900428976 DBDS10G1A/630V

R900346874 DBDS10G1A/630V/12

R900387485 DBDS10G1A/630VB

R900572353 DBDS10G1A/65B

R901260712 DBDS10G1A/65E

R900496233 DBDS10G1A/700

R900580506 DBDS10G1A/700V

R900572349 DBDS10G1A/70B

R900769413 DBDS10G1A/70E

R901158400 DBDS10G1A/70VE

R900572350 DBDS10G1A/80B

R900423740 DBDS10G1A/80B

R901002782 DBDS10G1A/80E

R900572351 DBDS10G1A/90B

R901167026 DBDS10G1A/95E

擠出機(jī)是屬于塑料機(jī)械的種類之一

擠出機(jī)依據(jù)機(jī)頭料流方向以及螺桿中心線的夾角,可以將機(jī)頭分成直角機(jī)頭和斜角機(jī)頭等。

螺桿擠出機(jī)是依靠螺桿旋轉(zhuǎn)產(chǎn)生的壓力及剪切力,能使得物料可以充分進(jìn)行塑化以及均勻混合,通過口模成型。塑料擠出機(jī)可以基本分類為雙螺桿擠出機(jī),單螺桿擠出機(jī)以及不多見的多螺桿擠出機(jī)以及無螺桿擠出機(jī)。

在擠出機(jī)中,一般情況下,基本和通用的是單螺桿擠出機(jī)。其主要包括:傳動(dòng)、加料裝置、料筒、螺桿、機(jī)頭和口模等六個(gè)部分。

傳動(dòng)部分

傳動(dòng)部分通常由電動(dòng)機(jī),減速箱和軸承等組成。在擠出的過程中,螺桿轉(zhuǎn)速必須穩(wěn)定,不能隨著螺桿負(fù)荷的變化而變化,這樣才能保持所得制品的質(zhì)量均勻一致。但是在不同的場(chǎng)合下又要要求螺桿可以變速,以達(dá)到一臺(tái)設(shè)備可以擠出不同塑料或不同制品的要求。因此,本部分一般采用交流整流子電動(dòng)機(jī)、直流電動(dòng)機(jī)等裝置,以達(dá)到無級(jí)變速,一般螺桿轉(zhuǎn)速為10~100轉(zhuǎn)/分。

傳動(dòng)系統(tǒng)的作用是驅(qū)動(dòng)螺桿,供給螺桿在擠出過程中所需要的力矩和轉(zhuǎn)速,通常由電動(dòng)機(jī)、減速器和軸承等組成。而在結(jié)構(gòu)基本相同的前提下,減速機(jī)的制造成本大致與其外形尺寸及重量成正比。因?yàn)闇p速機(jī)的外形和重量大,意味著制造時(shí)消耗的材料多,另所使用的軸承也比較大,使制造成本增加。

同樣螺桿直徑的擠出機(jī),高速的擠出機(jī)比常規(guī)的擠出機(jī)所消耗的能量多,電機(jī)功率加大一倍,減速機(jī)的機(jī)座號(hào)相應(yīng)加大是必須的。但高的螺桿速度,意味著低的減速比。同樣大小的減速機(jī),低減速比的與大減速比的相比,齒輪模數(shù)增大,減速機(jī)承受負(fù)荷的能力也增大。因此減速機(jī)的體積重量的增大,不是與電機(jī)功率的增大成線性比例的。如果用擠出量做分母,除以減速機(jī)重量,高速的擠出機(jī)得數(shù)小,普通擠出機(jī)得數(shù)大。以單位產(chǎn)量計(jì),高速擠出機(jī)的電機(jī)功率小及減速機(jī)重量小,意味著高速擠出機(jī)的單位產(chǎn)量機(jī)器制造成本比普通擠出機(jī)低。

加料裝置

供料一般大多采用粒料,但也可以采用帶狀料或者粉料。裝料設(shè)備通常都使用錐形加料斗,其容積要求至少能提供一個(gè)小時(shí)的用量。料斗底部有截?cái)嘌b置,以便調(diào)整和切斷料流,在料斗的側(cè)面裝有視孔和標(biāo)定計(jì)量的裝置。有些料斗還可能帶有防止原料從空氣中吸收水分的減壓裝置或者加熱裝置,或者有些料筒還自帶攪拌器,能為其自動(dòng)上料或加料。

料筒

一般為一個(gè)金屬料桶,為合金鋼或者內(nèi)襯為合金鋼的復(fù)合鋼管制成。其基本特點(diǎn)為耐溫耐壓強(qiáng)度較高,堅(jiān)固耐磨耐腐蝕。一般料筒的長(zhǎng)度為其直徑的15~30倍,其長(zhǎng)度以使物料得到充分加熱和塑化均勻?yàn)樵瓌t。料筒應(yīng)該有其足夠的厚度與剛度。內(nèi)部應(yīng)該光滑,但是有些料筒刻有各種溝槽,以增大與塑料的摩擦力。在料筒外部附有電阻、電感以及其他方式加熱的電熱器、溫度自控裝置及冷卻系統(tǒng)。

螺桿

螺桿是擠出機(jī)的關(guān)鍵部件,螺桿的性能好壞,決定了一臺(tái)擠出機(jī)的生產(chǎn)率、塑化質(zhì)量、填加物的分散性、熔體溫度、動(dòng)力消耗等。是擠出機(jī)重要的部件,它可以直接影響到擠出機(jī)的應(yīng)用范圍和生產(chǎn)效率。通過螺桿的轉(zhuǎn)動(dòng)對(duì)塑料產(chǎn)生極壓的作用,塑料在料筒中才可以發(fā)生移動(dòng)、增壓以及從摩擦中獲取部分熱量,塑料在料筒中移動(dòng)的過程中獲得混合和塑化,黏流態(tài)的熔體在被擠壓而流經(jīng)口模時(shí),獲得所需的形狀而成型。與料筒一樣,螺桿也是用高強(qiáng)度、耐熱和耐腐蝕的合金制備而成。

鍛壓機(jī)械是指在鍛壓加工中用于成形和分離的機(jī)械設(shè)備。鍛壓機(jī)械包括成形用的鍛錘、機(jī)械壓力機(jī)、液壓機(jī)、螺旋壓力機(jī)和平鍛機(jī),以及開卷機(jī)、矯正機(jī)、剪切機(jī)、鍛造操作機(jī)等輔助機(jī)械。鍛壓機(jī)械主要用于金屬成形,所以又稱為金屬成形機(jī)床。鍛壓機(jī)械是通過對(duì)金屬施加壓力使之成形的,力大是其基本特點(diǎn),故多為重型設(shè)備,設(shè)備上多設(shè)有安全防護(hù)裝置,以保障設(shè)備和人身安全。

鍛壓機(jī)械主要包括各種鍛錘、各種壓力機(jī)和其他輔助機(jī)械。

鍛錘,由重錘落下或強(qiáng)迫高速運(yùn)動(dòng)產(chǎn)生的動(dòng)能對(duì)坯料做功,使之塑性變形的機(jī)械。鍛錘是常見、歷史悠久的鍛壓機(jī)械。它結(jié)構(gòu)簡(jiǎn)單,工作靈活,功能性強(qiáng)、使用面廣、易于維修,適用于自由鍛和模鍛。但震動(dòng)較大,較難實(shí)現(xiàn)自動(dòng)化生產(chǎn)。

鍛錘的工作原理

鍛錘靠高壓氣體突然釋放的能量驅(qū)動(dòng)上,下錘頭高速運(yùn)動(dòng),懸空對(duì)擊,是金屬塑性成形的鍛造方法。高速錘鍛造是一種高能率成形方法,主要用于精密模鍛和熱擠壓。

瞬間釋放的高壓氣體(壓力一般為15000兆帕,迫使錘頭向下作9~24米/秒的高速運(yùn)動(dòng),同時(shí)也向上推動(dòng)高壓氣缸的缸蓋,并帶動(dòng)整個(gè)機(jī)架向上運(yùn)動(dòng)。錘頭上的上模與機(jī)架上的下模在空中對(duì)擊工件,使之塑性變形。機(jī)架的質(zhì)量遠(yuǎn)大于錘體,所以移動(dòng)速度慢,行程小,便于操作。錘擊后,安裝在機(jī)架內(nèi)的回程桿將錘頭推回原處。機(jī)架放置于外支架的緩沖墊上。這類設(shè)備初只能一次單擊,后來研制出可以連擊的﹑內(nèi)燃式的高速錘。高速錘鍛造,存在明顯的變形慣性力和變形熱效應(yīng),控制得當(dāng)可以提高金屬的塑性,改善金屬在模具中的流動(dòng)充填性能,利用模鍛可成形薄壁﹑高肋的復(fù)雜形狀鍛件。高速錘鍛造多用于葉片﹑齒輪等零件的精鍛和擠壓。

一、液壓傳動(dòng)技術(shù)的應(yīng)用

液壓傳動(dòng)技術(shù)在近代工業(yè)制造中的應(yīng)用

液壓傳動(dòng)有許多突出的優(yōu)點(diǎn),因此它的應(yīng)用非常廣泛,如一般工業(yè)用的塑料加工機(jī)械、壓力機(jī)械、機(jī)床等,行走機(jī)械中的工程機(jī)械、建筑機(jī)械、農(nóng)業(yè)機(jī)械、汽車等;鋼鐵工業(yè)用的冶金機(jī)械、提升裝置、軋輥調(diào)整裝置等;土木水利工程用的防洪閘門及堤壩裝置、河床升降裝置、橋梁操縱機(jī)構(gòu)等,發(fā)電廠渦輪機(jī)調(diào)速裝置、發(fā)電廠等等。

二、液壓傳動(dòng)技術(shù)的原理與特點(diǎn)

1、液壓傳動(dòng)的介紹

液壓傳動(dòng)是用液體作為工作介質(zhì)來傳遞能量和進(jìn)行控制的傳動(dòng)方式。液壓傳動(dòng)和氣壓傳動(dòng)并稱為流體傳動(dòng),是根據(jù)17世紀(jì)帕斯卡提出的液體靜壓力傳動(dòng)原理而發(fā)展起來的一門新興技術(shù),是工農(nóng)業(yè)生產(chǎn)中應(yīng)用廣泛的技術(shù)。

2、液壓傳動(dòng)的優(yōu)點(diǎn)

(1)體積小、重量輕,因此慣性力較小,當(dāng)突然過載或停車時(shí),不會(huì)發(fā)生大的沖擊,

(2)能在給定范圍內(nèi)平穩(wěn)的自動(dòng)調(diào)節(jié)牽引速度,并可實(shí)現(xiàn)無極調(diào)速;

(3)換向容易,在不改變電機(jī)旋轉(zhuǎn)方向的情況下,可以較方便地實(shí)現(xiàn)工作機(jī)構(gòu)旋轉(zhuǎn)和直線往復(fù)運(yùn)動(dòng)的轉(zhuǎn)換;

(4)液壓泵和液壓馬達(dá)之間用油管連接,在空間布置上彼此不受嚴(yán)格限制;

(5) 由于采用油液為工作介質(zhì),元件相對(duì)運(yùn)動(dòng)表面間能自行潤(rùn)滑,磨損小,使用壽命長(zhǎng);

(6)操縱控制簡(jiǎn)便,自動(dòng)化程度高;

(7)容易實(shí)現(xiàn)過載保護(hù)。

液壓傳動(dòng)有許多突出的優(yōu)點(diǎn),因此它的應(yīng)用非常廣泛,如一般工業(yè)用的塑料加工機(jī)械、壓力機(jī)械、機(jī)床等,行走機(jī)械中的工程機(jī)械、建筑機(jī)械、農(nóng)業(yè)機(jī)械、汽車等,鋼鐵工業(yè)用的冶金機(jī)械、提升裝置、軋輥調(diào)整裝置等,土木水利工程用的防洪閘門及堤壩裝置、河床升降裝置、橋粱操縱機(jī)構(gòu)等;發(fā)電廠渦輪機(jī)調(diào)速裝置等等,船舶用的甲板起重機(jī)械、船頭門、艙壁閥、船尾推進(jìn)器等,特殊技術(shù)用的控制裝置、測(cè)量浮標(biāo)、升降旋轉(zhuǎn)舞臺(tái)等。

3、液壓傳動(dòng)的基本原理

液壓傳動(dòng)的基本原理是在密閉的容器內(nèi),利用有壓力的油液作為工作介質(zhì)來實(shí)現(xiàn)能量轉(zhuǎn)換和傳遞動(dòng)力的。其中的液體稱為工作介質(zhì),一般為礦物油,它的作用和機(jī)械傳動(dòng)中的皮帶、鏈條和齒輪等傳動(dòng)元件相類似。液壓傳動(dòng)是利用帕斯卡原理!帕斯卡原理是大概就是:在密閉環(huán)境中,向液體施加一個(gè)力,這個(gè)液體會(huì)向各個(gè)方向傳遞這個(gè)力!力的大小不變!液壓傳動(dòng)就是利用這個(gè)物理性質(zhì),向一個(gè)物體施加一個(gè)力,利用帕斯卡原理使這個(gè)力變大!從而起到舉起重物的效果!

液壓傳動(dòng)在閥門行業(yè)也得到很大的應(yīng)用,如閥門的機(jī)床制造加工設(shè)備、閥門]液壓試驗(yàn)設(shè)備、閥門的液壓傳動(dòng)裝置等。